What is the future of the prismatic lithium battery market?

Prismatic lithium batteries are recognized for their efficiency, compact form factor, and enhanced safety features. They find extensive applications in various industries, including consumer electronics, electric vehicles, renewable energy storage systems, and portable electronic devices. The increasing adoption of electric vehicles worldwide creates a substantial market for prismatic lithium batteries, as they offer a reliable and high-performance energy storage solution for electric mobility. Opportunities within the Prismatic Lithium Battery Market are abundant, fueled by advancements in technology and the expanding scope of applications.

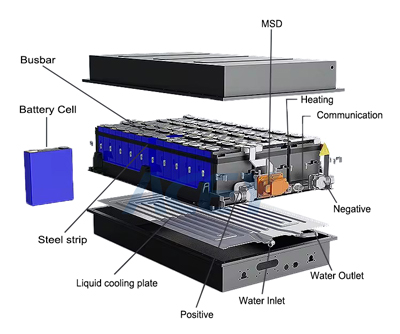

What are the components of a prismatic lithium battery pack?

The main materials of the prismatic lithium battery pack include prismatic battery cells, battery management system, steel strip/plastic steel strip, busbar, positive, negative, etc.

What are the applications of prismatic lithium battery packs?

Prismatic Lithium-ion batteries (square aluminum-cased lithium-ion batteries) have the advantages of high energy density, light weight, and long cycle life, and are widely used in a variety of fields, such as: Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs), Energy Storage Systems (ESS), Standby Power Supply (UPS), Electric Bicycle and Electric Motorcycle, Power tools, Aerospace and Military, Marine Applications, Medical Equipment, Robotics and automation equipment, Communication base stations and Ocean exploration equipment etc.

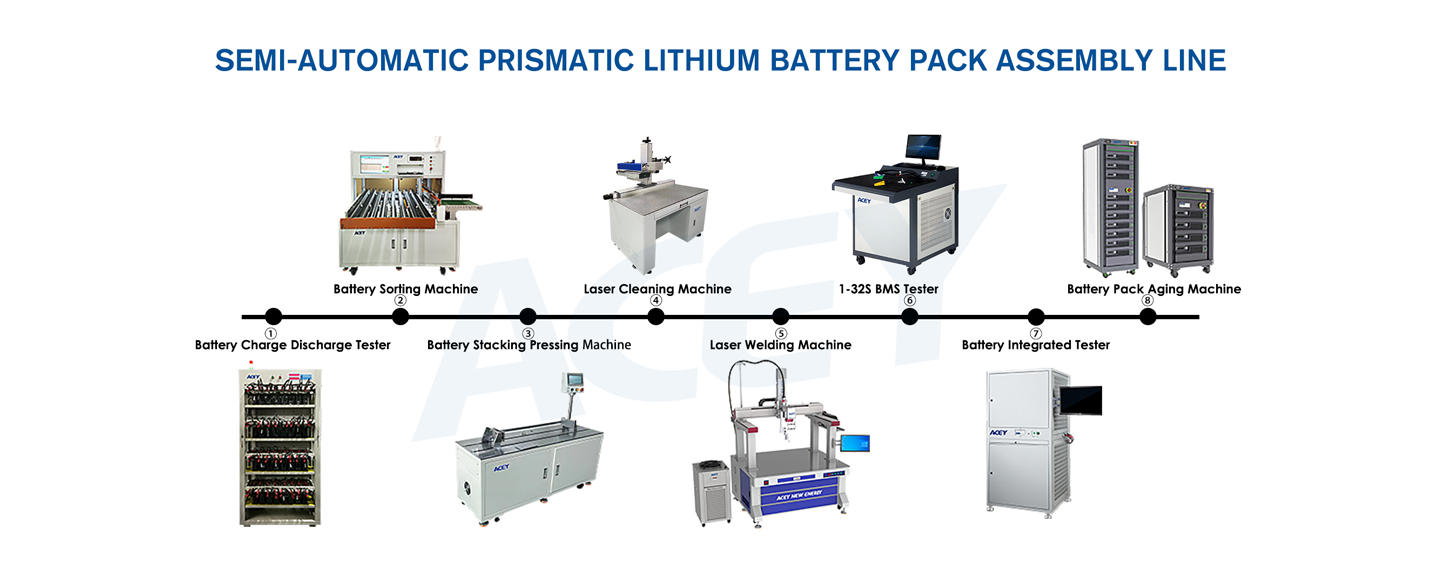

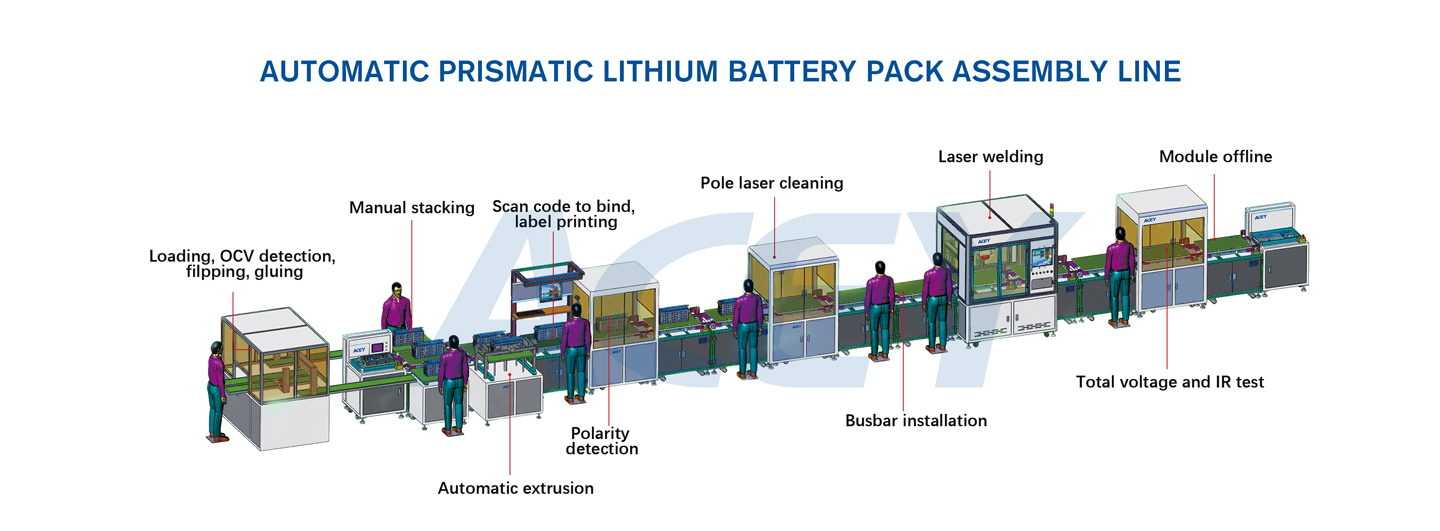

What equipment do you need to assemble a prismatic lithium battery pack?

The main equipment of prismatic battery pack assembly line include battery capacity grading machine, battery OCV&ACIR sorting machine, battery stacking and pressing machine, laser cleaning machine, laser welding machine, BMS tester, battery comprehensive tester, battery pack aging machine.

Option 1—— Semi-automatic prismatic lithium battery pack assembly line

Option 2—— Full-automatic prismatic lithium battery pack assembly line

What is the assembly process of prismatic lithium battery pack?

Step 1——Prismatic Cell Capacity Grading

1) Product Description

Prismatic cell capacity grading machine is used to test the capacity of prismatic batteries through cyclic charging and discharging tests to achieve the consistency of prismatic battery cells.

2) Working Principle and Features

The capacity sorting of Li-ion battery is screened by the cell capacity grading cabinet, the function of the cell capacity grading cabinet is similar to the charger, except that it can charge and discharge a large number of batteries at the same time.

Lithium batteries are managed by computer to get the data of each testing point, so as to analyze the size of these batteries' capacity and internal resistance and other data to determine the quality level of the batteries, and this process is capacity sorting.

3) Product Model

| Equipment Type | Energy-Feedback | Customized | |||||

| Battery Type | Prismatic battery | ||||||

| Clamps | Standard flat head fixture( optional alligator clip) | ||||||

| Voltage and Current | 5V20A | 5V30A | 5V60A | 5V100A | 5V200A | 6V300A | |

| Channels | 128CHS | 128/160CHS | 64CHS | 48CHS | 16/32CHS | 16CHS | |

| Product Picture |

|

|

|

|

|

|

More Products |

Step 2——Prismatic Cell OCV&ACIR Sorting

1) Product Description

Battery sorting machine is used in the prismatic lithium battery pack assembly line to test the open-circuit voltage and AC internal resistance of general prismatic lithium battery.

2) Working Principle and Features

Manually place the battery into the belt→The battery flows into the scanning position for code scanning→The battery flows into the test position for testing→The receiving mechanism accesses the corresponding channel for battery sorting.

3) Product Model

| Battery Type | Prismatic battery | Customized | |

| Barcode Scanner | Standard | ||

| Tester | HK3561/HIOKI BT3562 | ||

| Channels | 8 CHS | 10 CHS | |

| Product Picture |

|

|

|

Step 3——Prismatic Cell Stacking And Pressing

1) Product Description

Prismatic battery stacking and pressing machine is used to stack and shape prismatic lithium batteries and tie them with steel or plastic steel straps, making it convenient for battery assembly into the box.

2) Working Principle and Features

Prismatic battery stacking and pressing machine adopts servo motor+screw module+planetary reducer for stacking and extruding, controlled by pressure controller, the extrusion stacking thrust reaches more than 500KG(can be customized) and easy to operate.

3) Product Model

| Battery Type | Prismatic battery | Customized | |

| Control | PLC+Touch Screen Control | ||

| Strips | Plastic Steel Strips | Steel Strips | |

| Stacking Pressure | 100KG | 500KG | |

| Product Picture |

|

|

More Products |

Step 4——Prismatic Battery Terminal Laser Cleaning

1) Product Description

Laser cleaning machine is used in the assembly of prismatic lithium-ion battery packs to clean terminals, busbars, connectors, battery modules, housing surfaces, and BMS contact points, remove oxides, dust, and debris, to ensure strong and reliable electrical connections and appropriate thermal management.

2) Working Principle and Features

Fiber laser cleaning machines utilize high-energy laser pulses delivered through a fiber optic cable to remove contaminants, coatings, and impurities from surfaces.

3) Product Model

Step 5——Prismatic Battery Pack Laser Welding

1) Product Description

Laser welding machine for lithium ion batteries is mainly used in the assembly process of prismatic and pouch cell lithium-ion battery packs to weld the busbars to the battery cells, and assemble the battery cells into a complete battery pack through series and parallel connections to achieve efficient power distribution and connection within the battery pack.

2) Working Principle and Features

lithium battery laser welding machine uses a high-intensity laser beam to precisely and rapidly weld components of lithium battery packs, ensuring strong, reliable, and high-quality connections with minimal heat-affected zones.

3) Product Model

| Welding Battery Type | Prismatic Lithium Batteries | Customized | ||

| Welding Materials | Nickel, Aluminium, Composite material, etc | |||

| Welding Method | Automatic | Manual | ||

| Product Type | Gantry | Handheld | ||

| Power | 1500W-6000W | 1500W-6000W | 1500W/2000W/3000W | |

| Welding Thickness | Specific welding thickness depends on the actual welding material | |||

| 0.5-5.8mm | 0.5-5.8mm | 0.3-3.5mm | ||

| Product Picture |

|

|

|

More Products |

Step 6——Battery Management System Testing

1) Product Description

BMS tester is used in the safety test of lithium battery protection board, to detect whether the functional indicators of the protection board are within the reasonable parameters.

2) Working Principle and Features

BMS tester uses capacitance to simulate battery charge and discharge, and conducts overcharge test, overcharge recovery test, overdischarge test, overdischarge protection recovery test, standby power consumption test, overcurrent test, etc. for the protection board.

3) Product Model

| Pack Series | 1-52S Battery Pack/Module | Customized | ||

| Current | 120/150/200/300/400/500/600/800A etc | |||

| Computer | With | |||

| Product Picture |

|

|

|

More Products |

Step 7——Prismatic Battery Pack Comprehensive Testing

1) Product Description

Battery comprehensive tester is suitable for all lithium-ion battery packs with CH+P+CH - P - ports to test various comprehensive performance parameters of the battery pack. The main test items include: open circuit voltage, AC internal resistance, discharge test, discharge over current test, short circuit protection test, charge test and charge protection test. The main test items are test open circuit voltage, AC internal resistance continuous charging current, continuous charging voltage, continuous discharging current, continuous discharging voltage, charging overcurrent protection current, discharging overcurrent protection current, short-circuit protection time, overcurrent delay time, and post-test voltage etc.

2) Working Principle and Features

The battery comprehensive tester is to apply a load to the battery or apply a small AC current to measure the open circuit voltage, AC internal resistance, discharge test, discharge overcurrent test, short circuit protection test, charge test and charge protection test and other parameters to quickly screen and judge the performance of the battery and good or bad, by setting the upper and lower limits of the measurement parameters, it is easy to quickly detect the bad battery from a batch of finished batteries.

3) Product Model

| Voltage | 50/60/100/120V/200V etc | Customized | ||

| Current | 120/200/300/500/600A etc | |||

| Product Picture |

|

|

|

More Products |

Step 8-Prismatic Battery Pack Aging Testing

1) Product Description

The battery pack life cycle tester is used to test the capacity, cycle life, charging/discharging characteristics and temperature characteristics, etc of lithium ternary, lithium iron phosphate, lead-acid, nickel-metal hydride, nickel-cadmium and other battery packs.

2) Working Principle and Features

Battery pack life cycle tester system mainly includes PC software, USB hub, router, aging instrument. The core lies in the aging instrument, the main control chip of the aging instrument is 32-bit ARM chip, which is much faster than the traditional microcontroller in execution and has higher accuracy in measuring voltage and current. The device has four test steps: charging, discharging, shelving, and cycling. By editing the corresponding steps, the battery can be tested in accordance with the set process.

3) Product Model

| Type | Linear | Energy-Feedback | Customized | ||||

| Voltage | 20V-1650V | ||||||

| Current | 10A-1200A | ||||||

| Channels | 1/2/3/4/6/7/8/12/16/32 etc | ||||||

| Product | Voltage&Current | 30V 10A charge 20A discharge | 100V 10A charge 20A discharge | 120V 150A charge 150A discharge | 200V 300A charge 300A discharge | 1000V 400A charge 400A discharge |

|

| Picture |

|

|

|

|

|

||